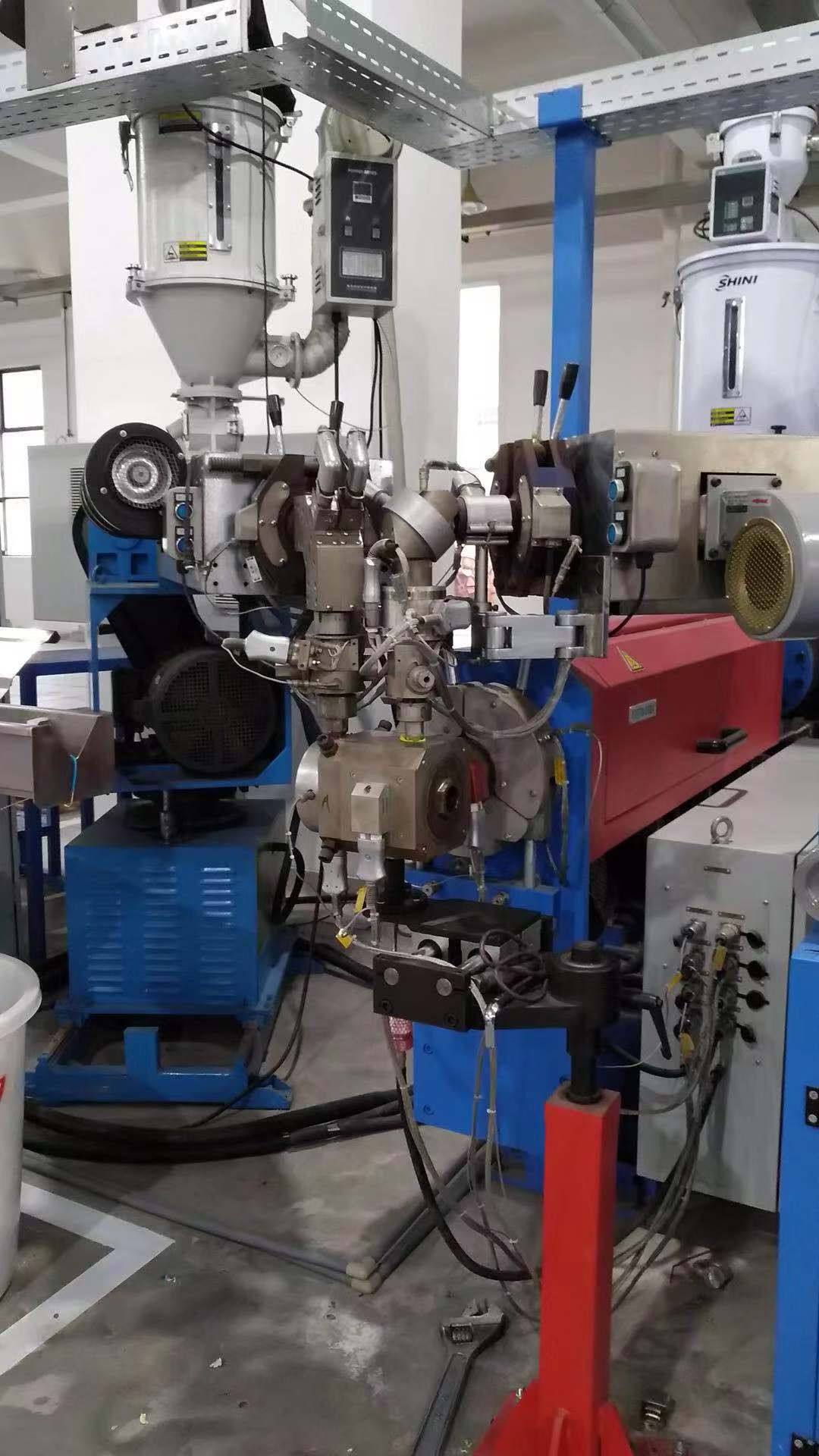

Waya na-arụ ọrụ nke ọma na USB Extruders

Ndị isi agwa

1, nakweere alloy magburu onwe ya mgbe ọgwụgwọ nitrogen maka ịghasa na gbọmgbọm, ndụ kwụsiri ike na ogologo ndụ.

2, kpo oku na jụrụ usoro pụrụ iche e mere mgbe okpomọkụ nwere ike ịtọ ke nso nke 0-380 ℃ na elu-nkenke akara.

3, ọrụ enyi na enyi site na ihuenyo mmetụ PLC

4, L / D ruru nke 36: 1 maka ngwa USB pụrụ iche (ụfụfụ anụ ahụ wdg)

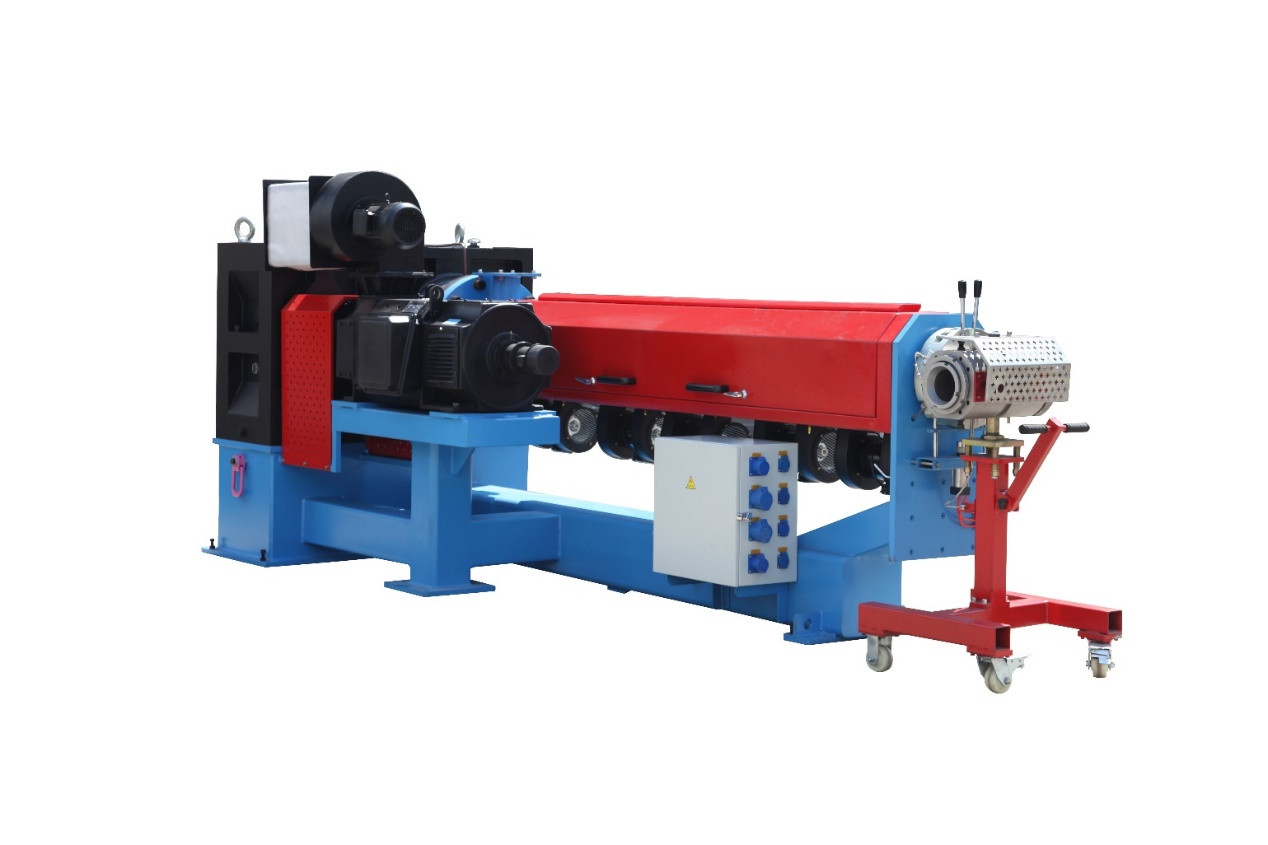

1.High arụmọrụ extrusion igwe

Ngwa: A na-ejikarị maka mkpuchi ma ọ bụ n'ọbọ extrusion nke wires na eriri

| Nlereanya | Oke ihe nkedo | Ikike mbupụ (kg/h) | Isi moto ike (kw) | dia waya ọpụpụ.(mm) | ||||

| Dia.(mm) | Oke L/D | Ọsọ (rpm) | PVC | LDPE | LSHF | |||

| 30/25 | 30 | 25:1 | 20-120 | 50 | 30 | 35 | 11 | 0.2-1 |

| 40/25 | 40 | 25:1 | 20-120 | 60 | 40 | 45 | 15 | 0.4-3 |

| 50/25 | 50 | 25:1 | 20-120 | 120 | 80 | 90 | 18.5 | 0.8-5 |

| 60/25 | 60 | 25:1 | 15-120 | 200 | 140 | 150 | 30 | 1.5-8 |

| 70/25 | 70 | 25:1 | 15-120 | 300 | 180 | 200 | 45 | 2-15 |

| 75/25 | 75 | 25:1 | 15-120 | 300 | 180 | 200 | 90 | 2.5-20 |

| 80/25 | 80 | 25:1 | 10-120 | 350 | 240 | 270 | 90 | 3-30 |

| 90/25 | 90 | 25:1 | 10-120 | 450 | 300 | 350 | 110 | 5-50 |

| 100/25 | 100 | 25:1 | 5-100 | 550 | 370 | 420 | 110 | 8-80 |

| 120/25 | 120 | 25:1 | 5-90 | 800 | 470 | 540 | 132 | 8-80 |

| 150/25 | 150 | 25:1 | 5-90 | 1200 | 750 | 700 | 250 | 35-140 |

| 180/25 | 180 | 25:1 | 5-90 | 1300 | 1000 | 800 | 250 | 50-160 |

| 200/25 | 200 | 25:1 | 5-90 | 1600 | 1100 | 1200 | 315 | 90-200 |

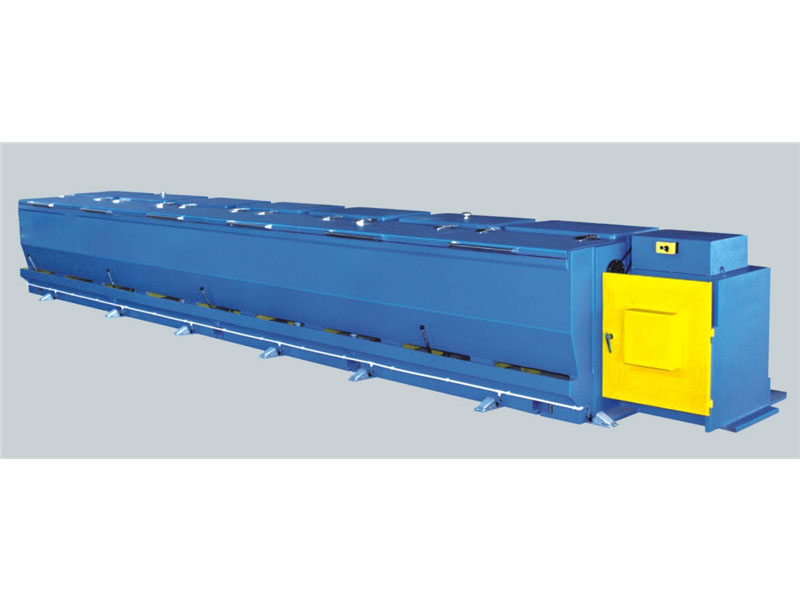

2.Double oyi akwa co-extrusion akara

Ngwa: Co-extrusion akara adabara ala anwụrụ ọkụ halogen free, XLPE extrusion, tumadi eji maka mmepụta nke nuklia ike ọdụ cables, wdg.

| Nlereanya | Oke ihe nkedo | Ikike mbupụ (kg/h) | dia waya mbata. (mm) | Obere waya dia. (mm) | Ọsọ ahịrị (m/min) | |

| Dia.(mm) | Oke L/D | |||||

| 50+35 | 50+35 | 25:1 | 70 | 0.6-4.0 | 1.0-4.5 | 500 |

| 60+35 | 60+35 | 25:1 | 100 | 0.8-8.0 | 1.0-10.0 | 500 |

| 65+40 | 65+40 | 25:1 | 120 | 0.8-10.0 | 1.0-12.0 | 500 |

| 70+40 | 70+40 | 25:1 | 150 | 1.5-12.0 | 2.0-16.0 | 500 |

| 80+50 | 80+50 | 25:1 | 200 | 2.0-20.0 | 4.0-25.0 | 450 |

| 90+50 | 90+50 | 25:1 | 250 | 3.0-25.0 | 6.0-35.0 | 400 |

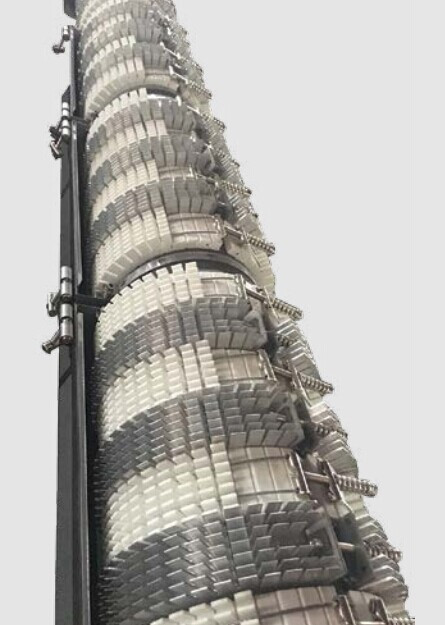

3.Triple-extrusion akara

Ngwa: Triple-extrusion ahịrị dabara adaba maka obere anwụrụ ọkụ halogen n'efu, extrusion XLPE, nke a na-ejikarị maka imepụta eriri ọdụ ọdụ nuklia, wdg.

| Nlereanya | Oke ihe nkedo | Ikike mbupụ (kg/h) | dia waya mbata. (mm) | Ọsọ ahịrị (m/min) | |

| Dia.(mm) | Oke L/D | ||||

| 65+40+35 | 65+40+35 | 25:1 | 120/40/30 | 0.8-10.0 | 500 |

| 70+40+35 | 70+40+35 | 25:1 | 180/40/30 | 1.5-12.0 | 500 |

| 80+50+40 | 80+50+40 | 25:1 | 250/40/30 | 2.0-20.0 | 450 |

| 90+50+40 | 90+50+40 | 25:1 | 350/100/40 | 3.0-25.0 | 400 |