Igwe mkpochapụ na-aga n'ihu

Uru

1, plastic deformation nke nri mkpara n'okpuru esemokwu ike na elu okpomọkụ nke na-ekpochapụ n'ime ime na mkpara n'onwe ya kpamkpam iji hụ na ikpeazụ ngwaahịa na magburu onwe ngwaahịa arụmọrụ na elu akụkụ ziri ezi.

2, ọ bụghị preheating ma ọ bụ annealing, ezigbo mma ngwaahịa nwetara site extrusion usoro na ala ike oriri.

3, na-eji otu mkpara na-eri nri, igwe nwere ike imepụta ụdị ngwaahịa dị iche iche site na iji ọnwụ dị iche iche.

4, ahịrị dum dị mfe na ngwa ngwa na-arụ ọrụ na-enweghị ọrụ dị arọ ma ọ bụ mmetọ n'oge extrusion.

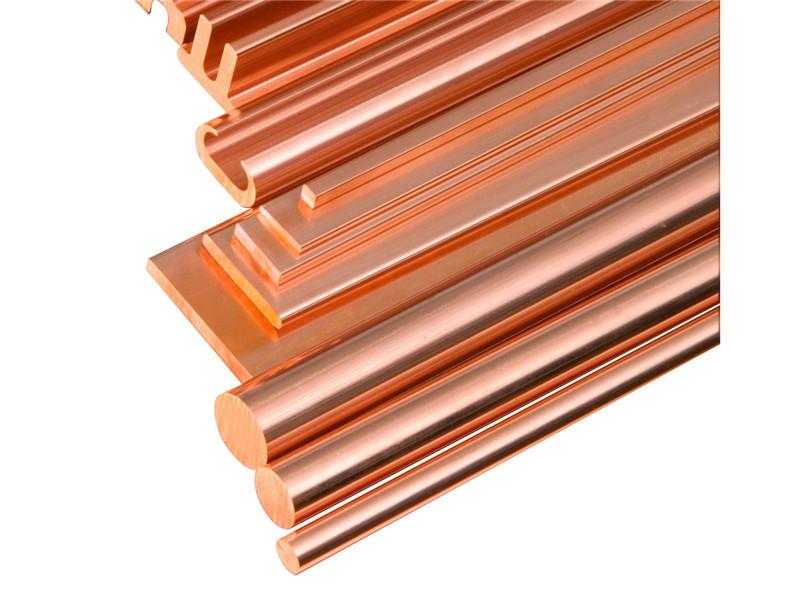

Nri mkpanaka ọla kọpa

1.To ime ka ọla kọpa ewepụghị wires, obere ọla kọpa busbar na gburugburu waya

| Nlereanya | TLJ 300 | TLJ 300H |

| Isi moto ike(kw) | 90 | 110 |

| mkpanaka nri dia.(mm) | 12.5 | 12.5 |

| Oke.obosara ngwaahịa (mm) | 40 | 30 |

| Flat Waya Cross-Sectional | 5-200 | 5-150 |

| Nsonaazụ (kg/h) | 480 | 800 |

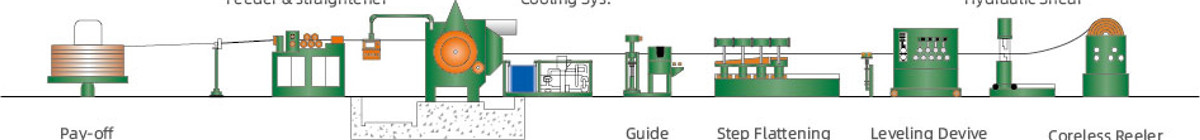

Nhazi ahịrị mmepụta

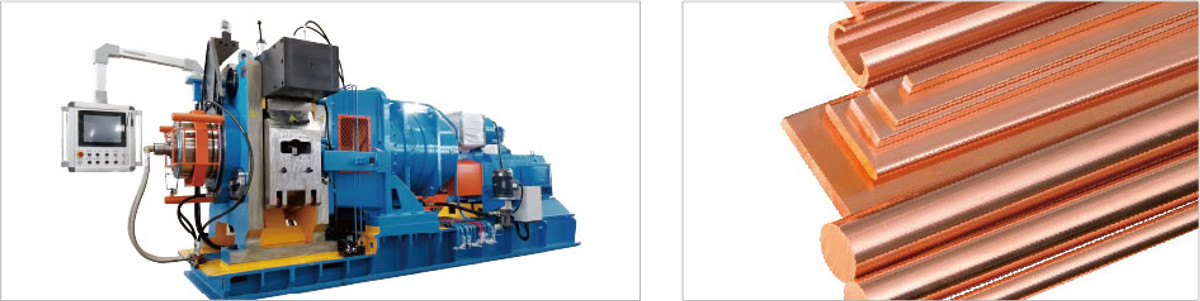

Igwe eji eme ihe nkwụghachi ụgwọ akwụ ụgwọ.Igwe eji agba egwu egwu

2.To ime ọla kọpa busbar, ọla kọpa gburugburu na ọla kọpa profaịlụ

| Nlereanya | TLJ 350 | TLJ 350H | TLJ 400 | TLJ 400H | TLJ 500 | TLJ 630 |

| isi moto (kw) | 160 | 200 | 250 | 315 | 355 | 600 |

| nri mkpanaka dia.(mm) | 16 | 16 | 20 | 20 | 25 | 30 |

| max.obosara ngwaahịa (mm) | 100 | 100 | 170 | 170 | 260 | 320 |

| mkpanaka ngwaahịa dia.(mm) | 4.5-50 | 4.5-50 | 8-90 | 8-90 | 12-100 | 12-120 |

| mpaghara obe-ngalaba ngwaahịa (mm2) | 15-1000 | 15-1000 | 75-2000 | 75-2000 | 300-3200 | 600-6400 |

| mmepụta (kg/h) | 780 | 950 | 1200 | 1500 | 1800 | 2800 |

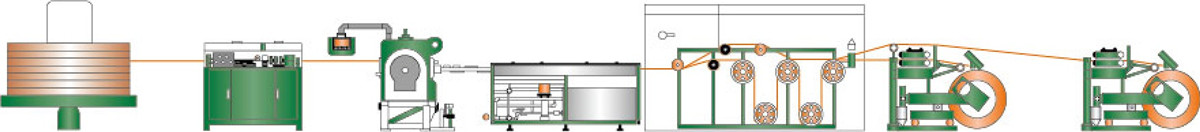

Nhazi ahịrị mmepụta

Feeder akwụ ụgwọ & straightener Extrusion Machine Cooling Sys.Igwe eji eji bench eme ihe ogologo Counter

3. Iji mee ọla kọpa busbar, eriri ọla kọpa

| Nlereanya | TLJ 500U | TLJ 600U |

| isi moto (kw) | 355 | 600 |

| nri mkpanaka dia.(mm) | 20 | 30 |

| max.obosara ngwaahịa (mm) | 250 | 420 |

| max.obosara ka ọkpụrụkpụ ruru | 76 | 35 |

| ọkpụrụkpụ ngwaahịa (mm) | 3-5 | 14-18 |

| mmepụta (kg/h) | 1000 | 3500 |

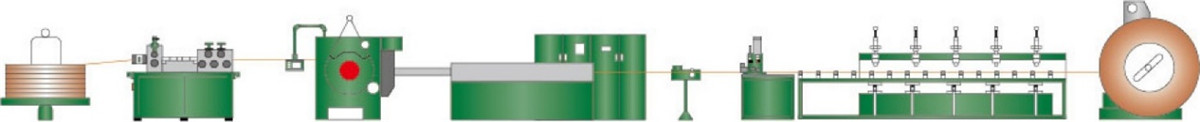

Nhazi ahịrị mmepụta

Nri osisi alloy ọla kọpa

Itinye akwụkwọ maka commutator conductor, Brass oghere, mkpanaka ọla kọpa phosphor, eriri etiti ụzọ, waya kọntaktị ụgbọ oloko wdg.

| TLJ 350 | TLJ 400 | TLJ 500 | TLJ 630 | |

| ihe | 1459/62/63/65 brass cu/Ag (AgsO.08%) | ọla kọpa phosphor (Pso.5%) cu/Ag (AgsO.3%) | ọla kọpa magnesium (MgsO.5%) ọla kọpa (Feso.l% | ọla kọpa magnesium (MgsO.7%)/Cucrzr |

| nri mkpanaka dia.(mm) | 12/12.5 | 20 | 20 | 25 |

| max.obosara ngwaahịa (mm) | 30 | 150 (obere ọla kọpa ọla kọpa) | 100 (okpukpu isi:) | 320 |

| mkpanaka ngwaahịa dia.(mm) | phosphor ọla kọpa: 10-40 | magnesium ọla kọpa: 20-40 | magnesium ọla kọpa: 20-40 | |

| mmepụta (kg/h) | 380 | 800-1000 | 1000-1200 | 1250/850 |

Nhazi ahịrị mmepụta

Feeder akwụ ụgwọ & straightener Extrusion Machine Cooling Sys.Igwe na-ebufe ogologo ogologo

Aluminom mkpara nri

Itinye akwụkwọ maka waya dị larịị, mmanya ụgbọ ala, na onye na-eduzi profaịlụ, tube okirikiri, MPE na Tubes PFC

| Nlereanya | LLJ 300 | LLJ 300H | LLJ 350 | LLJ 400 |

| isi moto (kw) | 110 | 110 | 160 | 250 |

| nri mkpanaka dia.(mm) | 9.5 | 9.5 | 2*9.5/15 | 2*12/15 |

| max.obosara nke ngwaahịa waya dị larịị (mm) | 30 | 30 | 170 | |

| Mpaghara cross ngalaba (mm2) ngwaahịa waya dị larịị | 5-200 | 5-200 | 25-300 | 75-2000 |

| gburugburu tube dia.(mm) | 5-20 | 5-20 | 7-50 | |

| obosara tube dị larịị (mm) | - | ≤40 | ≤70 | |

| ewepụghị waya / mmepụta tube (kg/h) | 160/160 | 280/240 | 260/260 | (600/900)/- |

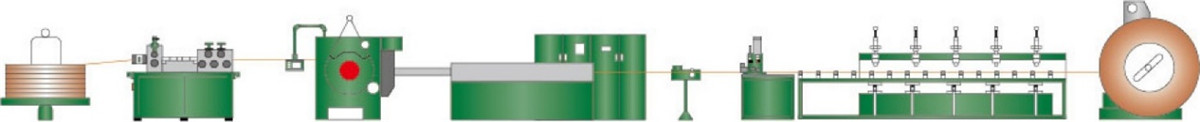

Nhazi ahịrị mmepụta

Pay-off straightener Ultrasonic Cleaning Cooling Sys Dancer Take-up Machine

Foto dị na 217282